We got more than 24 years of experience in the field of integrated, model based engineering. The methodology of “Virtual Solution Design” has been invented in 1994 by Jürgen Kaiser (ABB Transportation) and Dr.Christian Zeidler (ABB Research Heidelberg). A project team of the most experienced engineers of ABB and 6 research centers (ABB Heidelberg/GER, ABB Västeras/SE, ABB Baden/CH, Daimler Benz Berlin/GER, Daimler Benz Frankfurt/GER, FZI Karlsruhe/GER) developed the first CAPE tool on the WINDOWS platform under the lead of Jürgen Kaiser.

Almost every second light rail vehicle deployed in Germany has been engineered with CAPE/C since 1998, the predecessor of ESCAPE. ESCAPE has been developed by Capeware, a company founded in 1999 by Jürgen Kaiser and partners. It has been optimized for the needs of the automotive industry in many years of cooperation with BMW.

Since 2014 it is used to implement a fully integrated, model based engineering process for the development of a new passenger car platform in China. 3E supports the introduction of the process, trains chinese engineers in the methodology and develops transformation tools for the seamless integration of data from all the tools used in the different phases of the process. Thus we created the most efficient engineering environment for complex E/E-systems in automobiles available today. The first car developed with this platform will be on the roads soon.

A new generation of engineers with innovative ideas and an open mind is heading for the top. It is an honor for us being chosen to support them.

The methodology of Virtual Solution Design realized in ESCAPE supports the model based engineering of most complex electronically controlled products from a simple ECU to a complete power plant. The integration with model based development and simulation environments like MATLAB/Simulink provide a complete integrated tool chain from features and requirements down to serial production code and remote debugging with online access to the car’s data. The integrated engineering together with it’s Engineering Automation features can result in savings of up to a billion Euro a year according to BMW expectations from the specification of the AIDA project.

ESCAPE Datasheet

CAPE &

Virtual Solution Design

Introduction

Functional Network and Virtual Solution Design

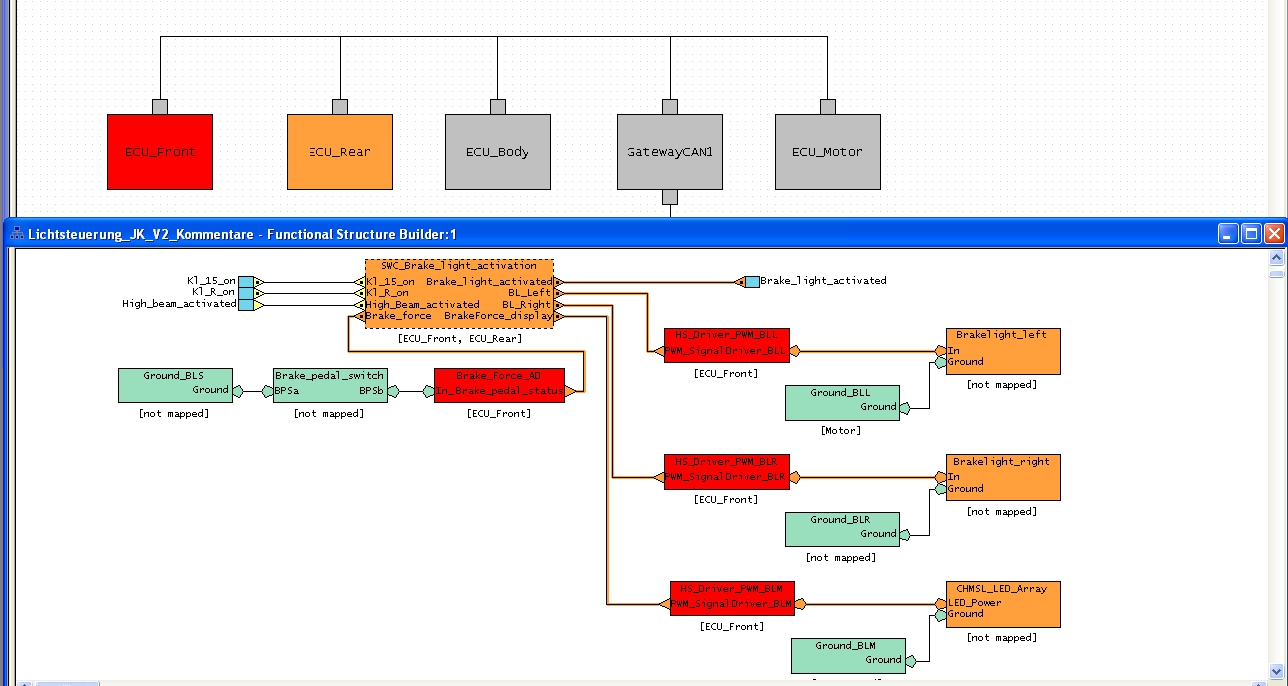

System architecture design und model based ECU development

Failure effects analysis - what happens in the case of faulty ECUs, functions, cables, messages

Fault back tracking - Search for the reason of faults, access real time variables via TCP/IP, force values remote

Data sheet (english)

Process (chinese)

Some screenshots from different phases of the engineering project:

„ESCAPE is the only tool that can build a model of an entire car“

Timo Boehme (SUMITOMO)

„This is not possible with ECLIPSE“

Sky Matthews (IBM),

ECLIPSE project manager / CTO Rational systems

„That scares me, I want to have that“

Morton Meyerson (2M Companies, Dallas)

ESCAPE